Problem

The manufacturers give high priority to Supply chain visibility Management Quality Control

Nowadays, the shipments move across various geographies, transfer through integrated supply chains, and change hands frequently. This can increase the possibilities of supply chain delays which may impact the production schedules of the manufacturers.

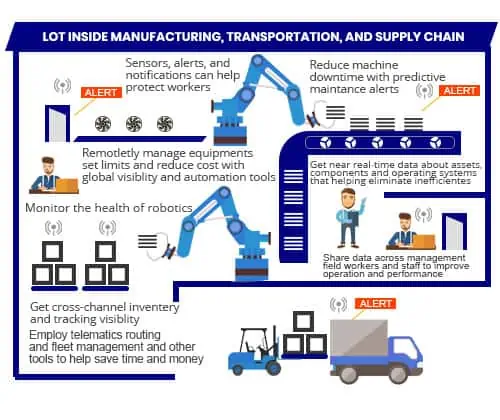

Most business leaders are choosing IoT to sense and adopt, address regulatory and compliance requirements, improve operational visibility, and respond to competitive pressures. Even though most of the businesses have IoT solutions in place today, approximately 87% of them are looking to expand their use and include more diverse sensor information as part of their data collection process.

Solution

From GPS to sensor logistics, moving beyond simple location tracking

The sensor-based visibility and IOT can enable

- Risk mitigation

- Clear up blind spots

- Help with quick response times

Eelink Asset Management – Operations Center has the potential to track your inbound supply chain component’s movement, location and the condition. It can also set the thresholds for humidity, temperature, impact, and ambient light intensity. You can establish geo fencing to determine if your supply chain components are outside of established boundaries.

By attaching an gps asset tracker to your supply chain shipments, you can manage and monitor your connected assets via Eelinktech Asset Management – Operations Center. The three important uses of sensors are measuring the speed, temperature and asset security.